Pick Lists

Videos for this articlePrinting a pick list

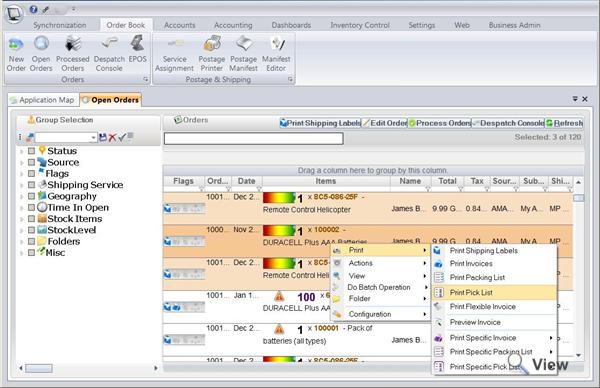

To print a pick list:

- Select the orders you want to print the pick list for

- Right click > Print > Print Pick List

- Once the pick list is printed, the system will add PICK_LIST history stamp to the audit trail for all printed orders

Configuring and customizing pick lists

Pick lists is based on a template. Therefore to change the layout and to specify what type of information you want to see on the pick list, you need to modify the pick list template.

- Settings > Template Designer

- Edit or add new templates to Pick List type

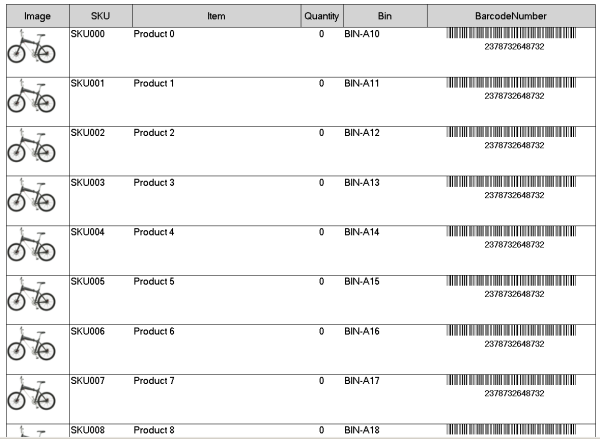

Adding and removing columns from the pick list

When the pick list is generated the quantity you need to pick is an aggregate of all selected fields. This means that the Quantity displayed on the pick list is broken down according what fields you have included on the pick list template. For example if you just include SKU and Quantity, Linnworks will simply count how many unique SKUs are in the selected orders (taking ordered quantity into account as well of course). Whereas if you include SKU, Source and Quantity. Linnworks will count how many unique SKUs for each Source you have selected and display that information only.

To add or remove new column to the pick list

- Go into Pick List template editing. (see How to Edit Templates)

- Edit the Items table (see How to Edit Tables in the Template Designer)

- Then make columns you want to see visible or invisible

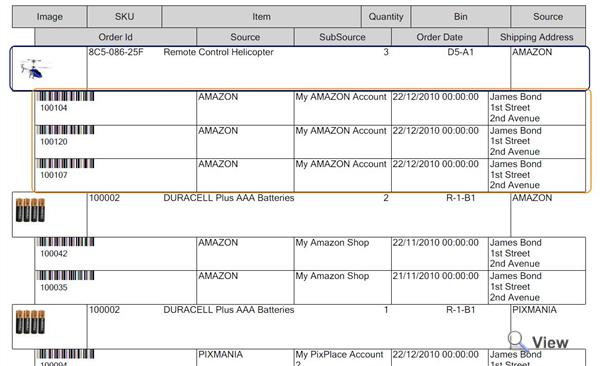

Include Order Information for each item on the list

You can configure the pick list to display each order for the item in the pick list underneath the item row. This is sometimes helpful if you want to use Pick list as a sole despatching reference and simply scan order ids directly from the Pick List to mark them off on the system as Despatched.

To enable order information for each pick list item row, you need to enable Sub Table for the Item table in the pick list:

- Go to Pick List template editor

- Edit the item table

- Sub-Table tab

- Show Sub-Table

Sorting the pick list by a specific column

- To sort the pick list by a column

- Edit the pick list template

- Edit the item table

- Set Sorting by clicking on the Sort Column (red = descending, green = ascending)

Using Pick List for Processing orders

Since the pick list is designed to give you a summary of what needs to be shipped for the selected orders, it is counter intuitive to think of a pick list something you can use to process orders. However, it is very efficient way of processing orders. Consider the following

- You print a pick list for all open orders

- Walk around in a predefined path (for example from bin to bin in one direction, since the pick list can be sorted by Bin/Rack location)

- Once everything is picked off the list, you go to the despatch station

- Open Despatch Console

- Start scanning barcodes of the products you have picked

- Linnworks comes up with the oldest order which contains the scanned product and lets you print label, print invoice and process the order.

So think of it as backwards order processing. Instead picking for every order individually you can pick all the items and then fit the orders to what you have picked.

Videos and Files

This video shows how to print packing lists in linnworks and how to customize the packing list info and layout. In addition we also make some suggestions regarding how the packing list can be used to reduce fulfilment time.

This video shows how to print pick lists in linnworks and how to customize the pick list info and layout. In addition we also make some suggestions regarding how the pick list can be used to reduce fulfilment time.